The First Step to Stronger SMB Supply Chains: Mapping What You Can’t See

Insights from Parth Davé, CCLP and founder of NexaFlux

Supply chain mapping creates a clear picture of how materials, information, and products move from suppliers to customers

For small and medium-sized businesses (SMBs), supply chains are often managed reactively - fixing problems only after they surface. But in today’s uncertain world, resilience and effectiveness aren’t optional; they’re survival. The first step toward both is supply chain mapping.

What is Supply Chain Mapping?

Supply chain mapping creates a clear picture of how materials, information, and products move from suppliers to customers. It reveals who your suppliers are, where they’re located, how goods flow, and where risks and inefficiencies hide.

Research by Interos (2021) shows 60% of Canadian companies cite single-source or single-geo supplier exposure as their top supply chain risk. Without mapping, these vulnerabilities stay invisible until disruption strikes.

And here’s the good news: mapping doesn’t require expensive software. Many SMBs can start with a simple Excel sheet or even a whiteboard, gradually layering in more detail.

Why Mapping is Foundational

Mapping is the baseline for all future decisions:

· Spotting weak points before they become costly failures

· Aligning procurement, logistics, and operations on one shared truth

· Moving from reactive firefighting to proactive planning

Most importantly, mapping lays the groundwork for a supply chain that is effective — one that delivers the right product, at the right time, to the right customer, even when disruptions hit.

A Practical Example: A Canadian Medical Device Company

Imagine a medium-sized Canadian medical device producer and distributor. They sell multiple brands across hospitals and clinics nationwide. Let’s focus on one device under one brand.

Step 1: Build the Map

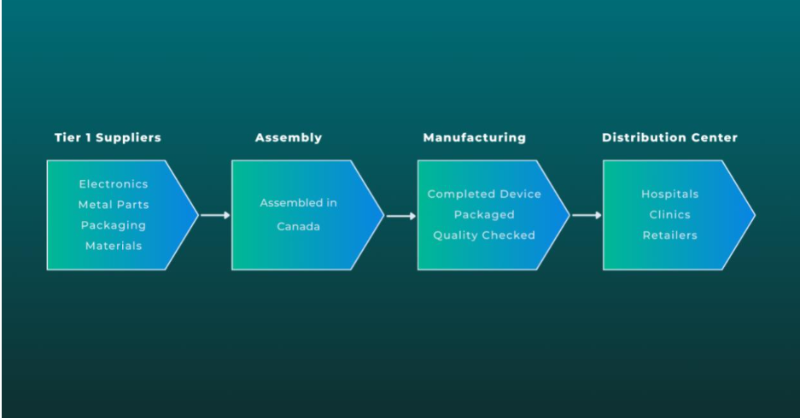

The map shows:

· Tier-1 suppliers: Electronics, metal parts, packaging materials

· Assembly: Canadian plant assembling components

· Manufacturing & Packaging: Device completed, packaged, and quality-checked

· Distribution center: Products shipped to hospitals, clinics, and retailers

From suppliers to customers, visibility is the foundation of an effective supply chain.

Step 2: Identify Opportunities

Mapping reveals that:

· Metal parts come from a single overseas supplier with long lead times

· Electronics rely on one contract manufacturer, creating a bottleneck

· Packaging suppliers are local and flexible - but underused

Step 3: Act for Resilience & Effectiveness

· Resilience: Qualify a second metal supplier within Canada or North America

· Effectiveness: Improve delivery reliability by consolidating shipments and leaning on local packaging partners

· Agility: Build stronger supplier partnerships for quicker response to demand changes

These aren’t costly overhauls. They’re practical, SMB-friendly steps that improve reliability and protect customers.

The Positive Impacts

By acting on these insights, the company could expect:

· Stronger visibility across supplier tiers, addressing the fact that 65% of organizations have experienced disruptions beyond Tier 1 and Tier 2 suppliers.

· A move toward transformation, with 63% of companies already adapting their supply chains to manage disruption, and leading innovators (93%) taking a holistic approach.

· Elevating resilience to a strategic advantage - 89% of business leaders now prioritize supply chain resilience as a core capability.

PwC research shows 73% of resilient companies outperform peers in total shareholder returns (PwC, 2021). For SMBs, the takeaway is clear: resilience makes your supply chain more effective, and effectiveness drives growth.

Hidden Insights for SMBs

The lesson isn’t just about mapping. It’s about shifting focus:

· Efficiency alone can make supply chains brittle

· Effectiveness ensures you meet customer needs, every time

· And here’s the twist: once you achieve effectiveness, efficiency follows naturally — smoother flows, fewer crises, more predictable operations

For SMBs, supply chain mapping is not a “big company” luxury. It’s the simplest, lowest-cost way to uncover vulnerabilities, strengthen customer service, and build a supply chain that is resilient, effective, and ready to grow.

Parth Davé, CCLP

Founder

NexaFlux

Parth Davé is the founder and principal consultant at NexaFlux Inc., a Canadian firm helping growing businesses turn data into stronger, more resilient supply chains. With over a decade of experience across transportation, healthcare, and consumer goods, he applies a constraint-first, systems-thinking lens to every engagement. Parth focuses on translating operational data into clear insights, measurable performance, and long-term competitive strength. Parth can be reached at pdave@nexafluxinc.com.